Resources

Carolina PEC specializes in the technical cleaning of various types of process equipment. From high value metallic filters, to heat exchangers unable to be cleaned in place, to highly specialized process equipment, our technical capability supports nearly every industry.

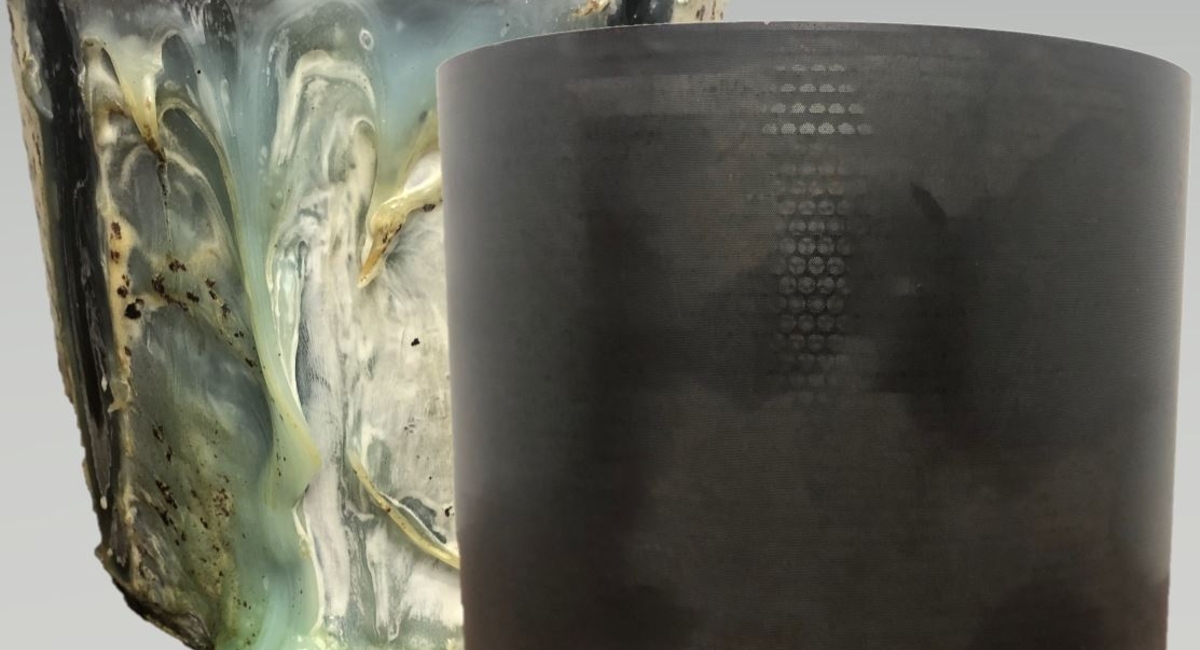

Filtration of Post-Consumer Recycled Material

Technical cleaning of systems used to filter post-consumer recycled additives.

Ettlinger Screen Cleaning

Processing to recover filtration surface area & inspecting to verify cleanliness

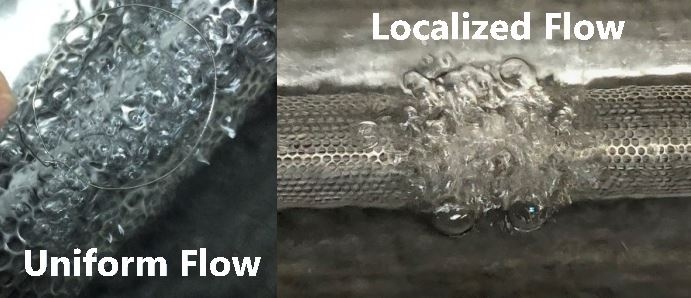

Enhanced Integrity Testing

Quantifying the degree of flow localization vs uniform flow across filter media

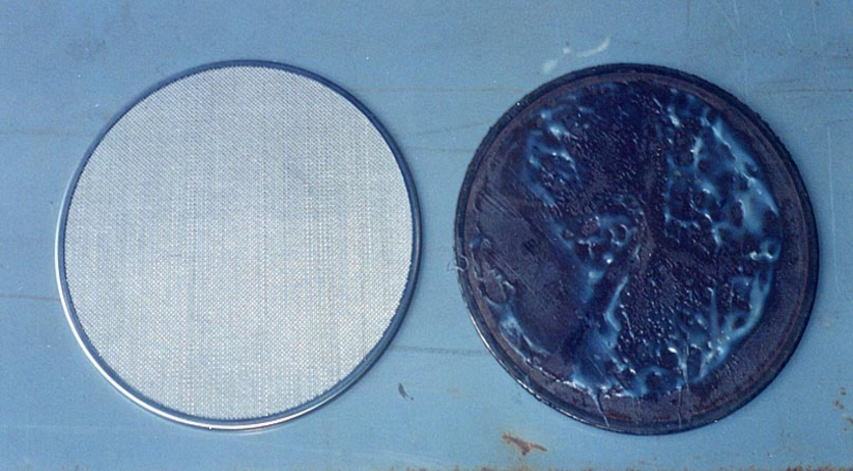

Cleanliness Testing for Metal Filters

Quantifying the degree of cleanliness in porous metal blowback filters

Bubble Point Testing for Filter Integrity

Carolina PEC offers bubble point testing for filter integrity, validating filters for reuse with standardized methods. Learn more.

DEECOM®: A Sustainable Process Used in Various Reclamation Processes

Learn more about DEECOM® technology, a solvent-free and relatively low temperature reclamation technology, is based on a pressure swing technique designed to physically disrupt and remove polymer from parts.

Effective Removal of Carbon from Fiber Metal Media

When carbon is the contaminant, special cleaning problems may be encountered. Removing carbon from filter media can be accomplished to varying degrees by physical and/or chemical means.

Methods of Polymer Removal

Download our FREE Methods of Polymer Removal Whitepaper! Learn the facts on recycling and reusing expensive parts and filters through polymer removal methods.

Reclamation of Shattered Metal Used in Synthetic Fiber Production

Download our FREE Reclamation of Shattered Metal Used in Synthetic Fiber Production Whitepaper! Shattered Metal Powder can be reclaimed utilizing various methods of depolymerization, separating, and sieving.

Ultrasonic Applications

Download our FREE Ultrasonic Application Whitepaper! When carbon is the contaminant, special cleaning problems may be encountered. Removing carbon from filter media can be accomplished to varying degrees by physical and/or chemical means.