Effective Removal of Carbon from Fiber Metal Media

Download our FREE Carbon Removal from Fiber Metal Media Whitepaper!

When carbon is the contaminant, special cleaning problems may be encountered. Removing carbon from filter media can be accomplished to varying degrees by physical and/or chemical means.

- Learn about the effect of high temperature oxidation (HTO) Process on Fiber Metal Media

- Understand filter selection and cleaning for a polymer or chemical

applications. - See the comparison of Oven and Salt Bath Processes.

Introduction:

Filtration is utilized in many applications in the polymer and chemical industries. Selection of a specific filter medium depends on application and process conditions. For those applications where metal filters are used, cleaning provides a way of reducing costs by reusing filters. When carbon is the contaminant, special cleaning problems may be encountered.

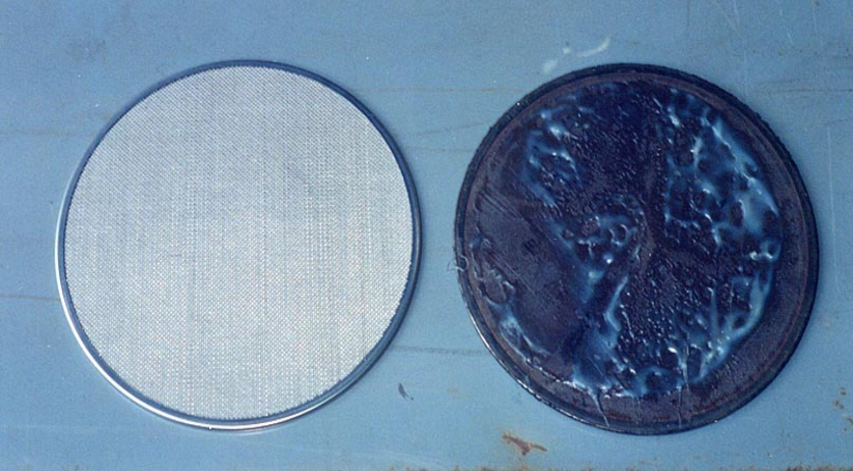

Removing carbon from filter media can be accomplished to varying degrees by physical and/or chemical means. Depending on the complexity of the media and the degree of carbon removal necessary to satisfy quality requirements, either of the methods can provide effective carbon removal.

However, as the degree of carbon removal becomes more critical and the structure of filter media becomes more complex, effective implies nearly 100% carbon removal from media composed of an intricate array of fine fibers. A process designed for complete carbon removal has the potential for damage to small fibers such as those used in fiber metal felt media.

As a result, the aggressiveness of the cleaning process must be carefully controlled and monitored to effectively remove carbon while minimizing the potential for damage.