Bubble Point Testing for Filter Integrity

What Is Bubble Point Testing?

Bubble point testing is a standardized method Carolina PEC uses to validate and evaluate filters for reuse, ensuring they meet the required performance standards. A bubble point test measures the pressure required to force liquid out of the largest pore of the filter media.

Most filter manufacturers perform this critical test before filters are shipped to customers, and Carolina PEC works with manufacturers who share this test data for reference. Each filter media type and micron rating will have a specific pressure range, making the bubble point test for filter integrity an essential tool in determining whether the largest pore of a filter aligns with the required or acceptable micron rating.

What Is Full Media Testing?

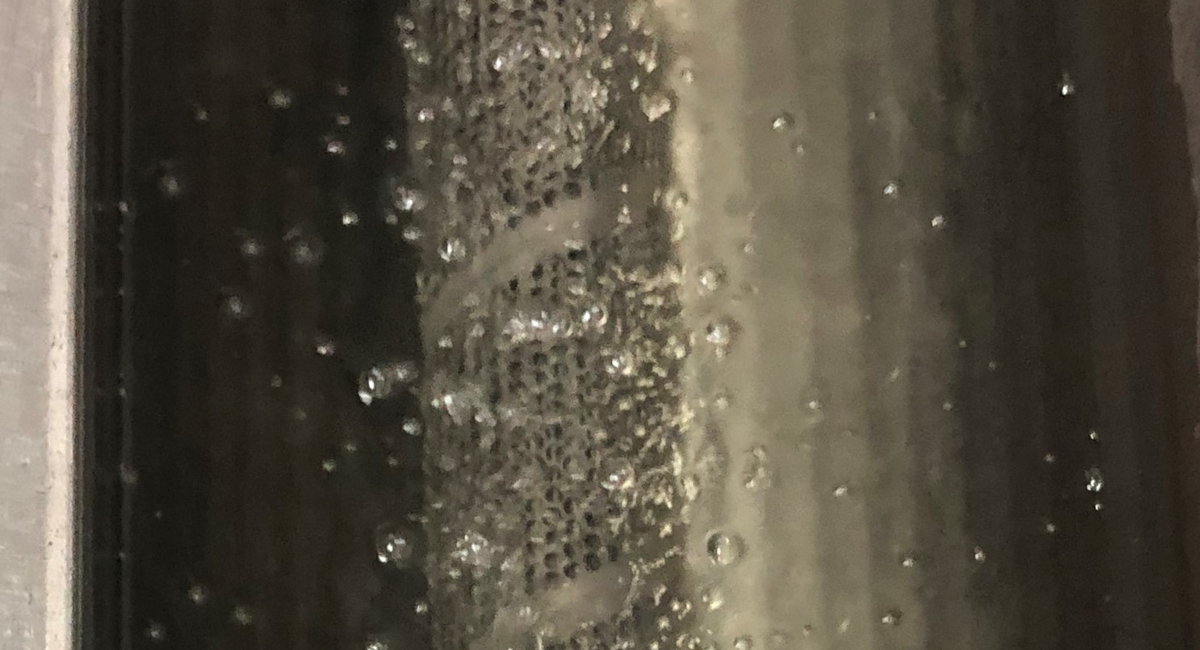

At Carolina PEC, we take integrity testing further with Full Media Testing, which expands on the bubble point test by providing a comprehensive measure of the overall pore size within the filter media.

Full Media Testing evaluates the filter's overall condition and identifies flow patterns—such as flow localization—across the filter surface. This advanced test is particularly useful for:

- Comparing baseline data with results after multiple cleaning cycles.

- Gaining actionable insights into the condition and performance of filters.

- Determining the significance of a low bubble point reading for better decision-making.

Why Bubble Point Testing Matters

By using bubble point testing and Full Media Testing, Carolina PEC helps clients:

- Validate filter performance before reuse.

- Extend the life of filters through accurate evaluation.

- Make informed decisions about filter maintenance and replacement.

These methods are part of our commitment to providing high-quality, reliable filtration solutions for a variety of industries.