Cleaning Breaker Plates in Extruders

The Role of Breaker Plates in Extrusion

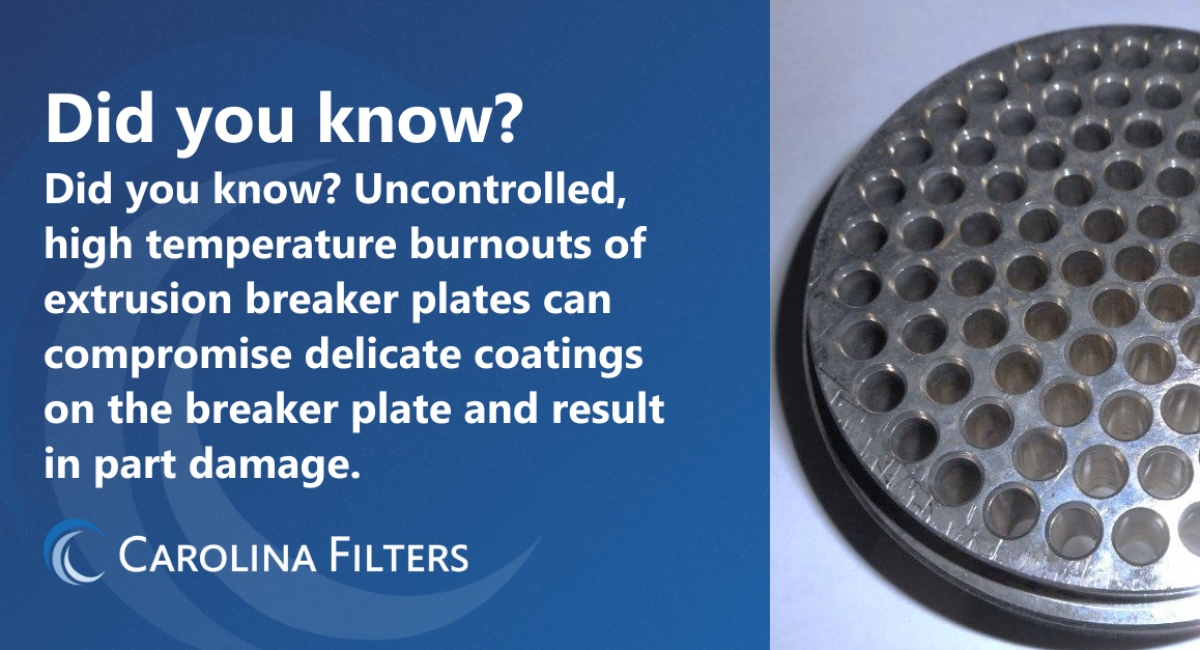

A breaker plate in an extruder plays a vital role in ensuring efficiency, product quality, and equipment protection during the extrusion process. Acting as coarse filtration, breaker plates:

- Remove large contaminants from the polymer stream.

- Provide uniform flow to optimize downstream processes.

- Protect critical components, such as fine filtration systems and die heads.

Keeping breaker plates clean is essential to maintaining the high standards necessary for producing quality extruded products. Contamination or flow restrictions caused by build-up on the plates can disrupt operations and compromise product quality.

Challenges of Cleaning Breaker Plates

While breaker plates are robust components, they often feature precision perforations and delicate surface coatings. Uncontrolled, high-temperature cleaning methods, such as burnouts, can:

- Compromise the integrity of precision-machined perforations.

- Damage delicate surface coatings essential for part performance.

- Lead to premature wear or failure, resulting in costly replacements.

Protecting these critical features ensures the breaker plate performs to the manufacturer's specifications and supports consistent, high-quality extrusion operations.

Carolina PEC's Controlled Cleaning Process

At Carolina PEC, we specialize in cleaning breaker plates in extruders using safe, controlled methods that preserve the part's integrity and its coating. Our process includes:

- Careful Polymer Removal: Employing methods to safely remove build-up without damaging the plate's surface or perforations.

- Customized Cleaning Solutions: Tailored to the materials and coatings of each breaker plate, ensuring compatibility and protection.

- Quality Assurance: After cleaning, we verify the plate's condition to confirm it meets manufacturer specifications for continued use.

Benefits of Choosing Carolina PEC for Breaker Plate Cleaning

- Preservation of Part Integrity: Our cleaning methods protect precision perforations and coatings, extending the life of your breaker plates.

- Enhanced Efficiency: Clean plates ensure optimal flow and contamination control, improving the performance of the extrusion process.

- Cost Savings: Prevent unnecessary damage or wear caused by aggressive cleaning techniques, reducing downtime and replacement costs.