Comprehensive Polymer Melt Filter Servicing at Carolina PEC

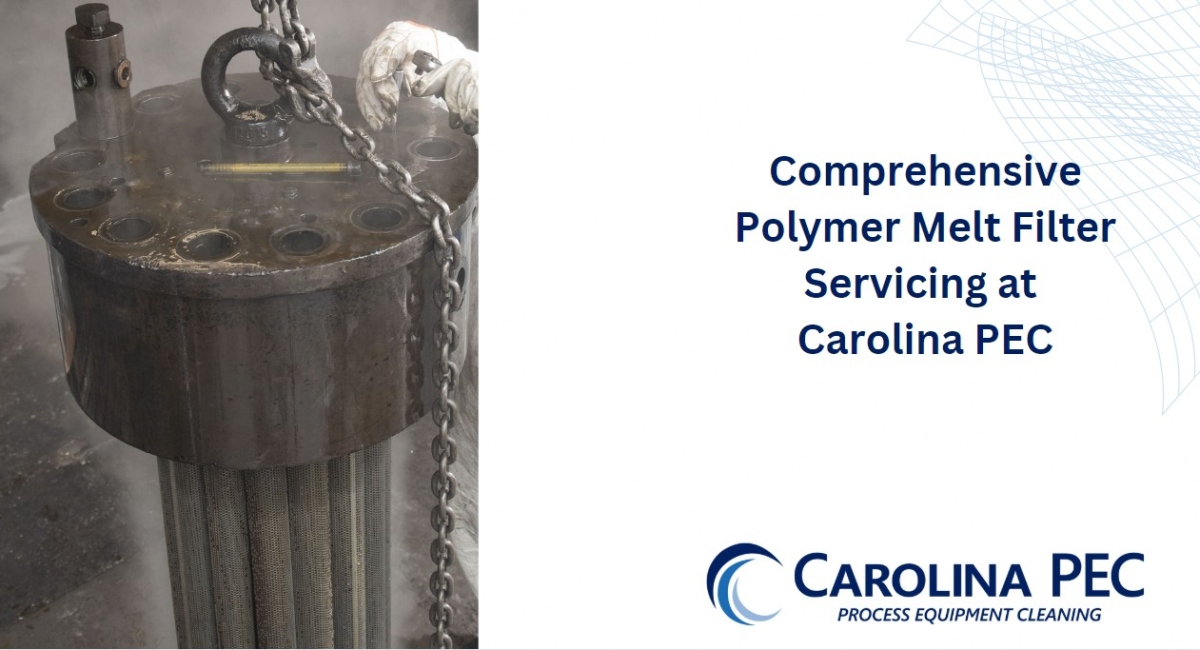

Servicing polymer melt filters involves more than just cleaning the filter elements. For top product quality, it’s essential to thoroughly clean all critical components—filter housings, stems, and tubesheets. At Carolina PEC, our skilled team provides a full turn-key solution: disassembling, cleaning, and reassembling all filter components for our customers.

With customer-provided spare elements, seals, and consumables, we handle every detail. Candle filters are conditioned, installed with fresh seals, and placed in cleaned canisters. Disc filters are reassembled on cleaned stems with new seals, properly preloaded, and leak-checked to guarantee a precise fit. Before shipment, we perform leak checks to ensure each canister meets our customers’ specifications.

Need reliable, end-to-end polymer filter servicing? Contact us to learn more about our meticulous process!