What we see

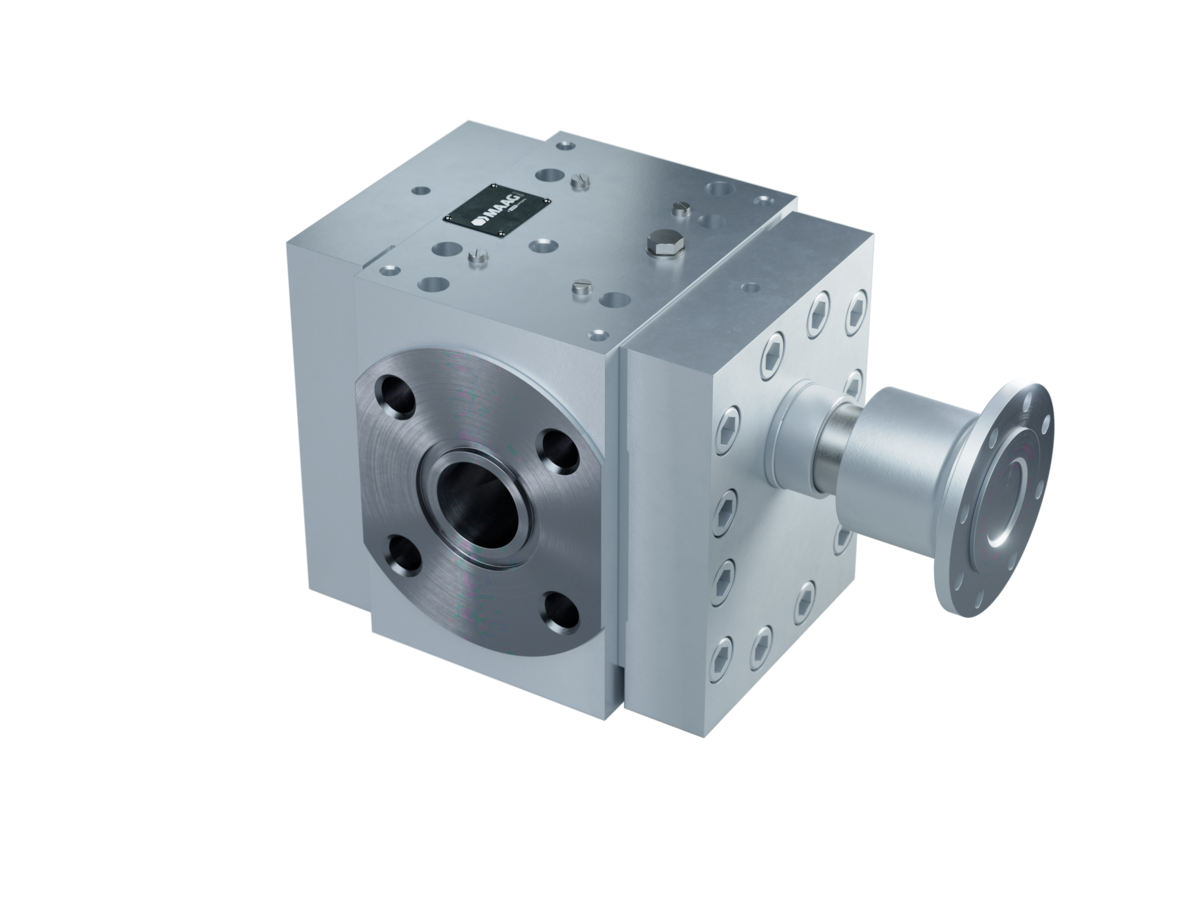

In polymer processing, pumps play a critical role in ensuring consistent product quality by precisely controlling flow rate and pressure. However, we often encounter pumps with significant polymer buildup, which can lead to a range of issues that disrupt production. Common problems include reduced flow rates, decreased efficiency, pressure fluctuations, and even damage to seals and gaskets. Over time, these deposits can cause malfunctions, increasing the risk of unplanned downtime and costly repairs.

The internal components of polymer pumps are particularly susceptible to fouling from accumulated residue, which is challenging to remove without causing further wear. Identifying these issues early is crucial to prevent performance degradation and extend the life of the pump.

What we do

At Carolina Process Equipment Cleaning (Carolina PEC), we use specialized cleaning methods to safely remove polymer buildup from pumps without compromising their integrity. Our process begins with a detailed assessment of the pump's condition, followed by the selection of the most effective cleaning technique. We utilize methods such as solvent soaking and controlled vacuum pyrolysis, tailored to break down and dissolve residues while protecting sensitive internal components.

Our comprehensive approach ensures that polymer pumps are thoroughly cleaned, restoring optimal flow and pressure control. By maintaining the efficiency and longevity of your pumps, we help you minimize downtime and keep your production process running smoothly.