What we see

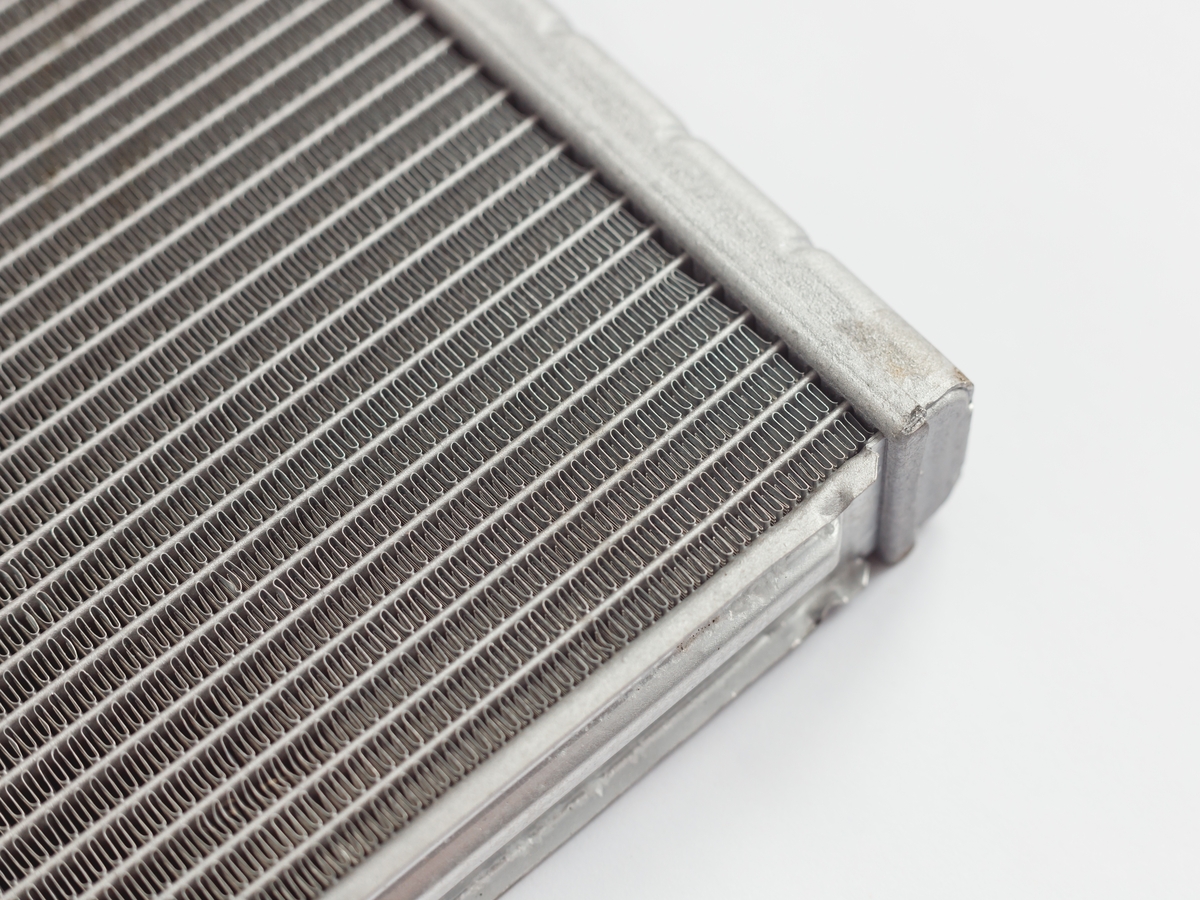

In many industrial processes, mist eliminator screens (demisters or entrainment separators) often experience a buildup of oils, particulates, and residue that hinders their efficiency. Over time, these contaminants reduce the performance of mist separation, leading to increased pressure drops and potential equipment failures. We frequently see screens clogged with stubborn deposits that are difficult to remove with standard cleaning methods, compromising the system's overall operation.

Our expertise allows us to quickly identify these issues and provide tailored cleaning solutions that address common problems associated with mist eliminator screens. By understanding the specific challenges your equipment faces, we can help restore your screens to their optimal performance, minimizing downtime and extending their service life.

What we do

Our cleaning process for metallic mist eliminator screens involves a multi-step approach which combines chemical treatment, high-temperature oxidation, and high-volume flushing. The screens are first removed and immersed in specialized chemical solutions that dissolve accumulated oils, particulates, and other residues. This treatment effectively loosens contaminants without damaging the metal structure. Residual organics are removed through high-temperature oxidation steps.

After the soaking and heat treatment phases, we use high-volume flushing with water or a suitable cleaning agent to dislodge and remove remaining debris. This thorough rinse ensures a complete restoration of the screens, returning them to their original efficiency and ready for reliable performance in your industrial systems.