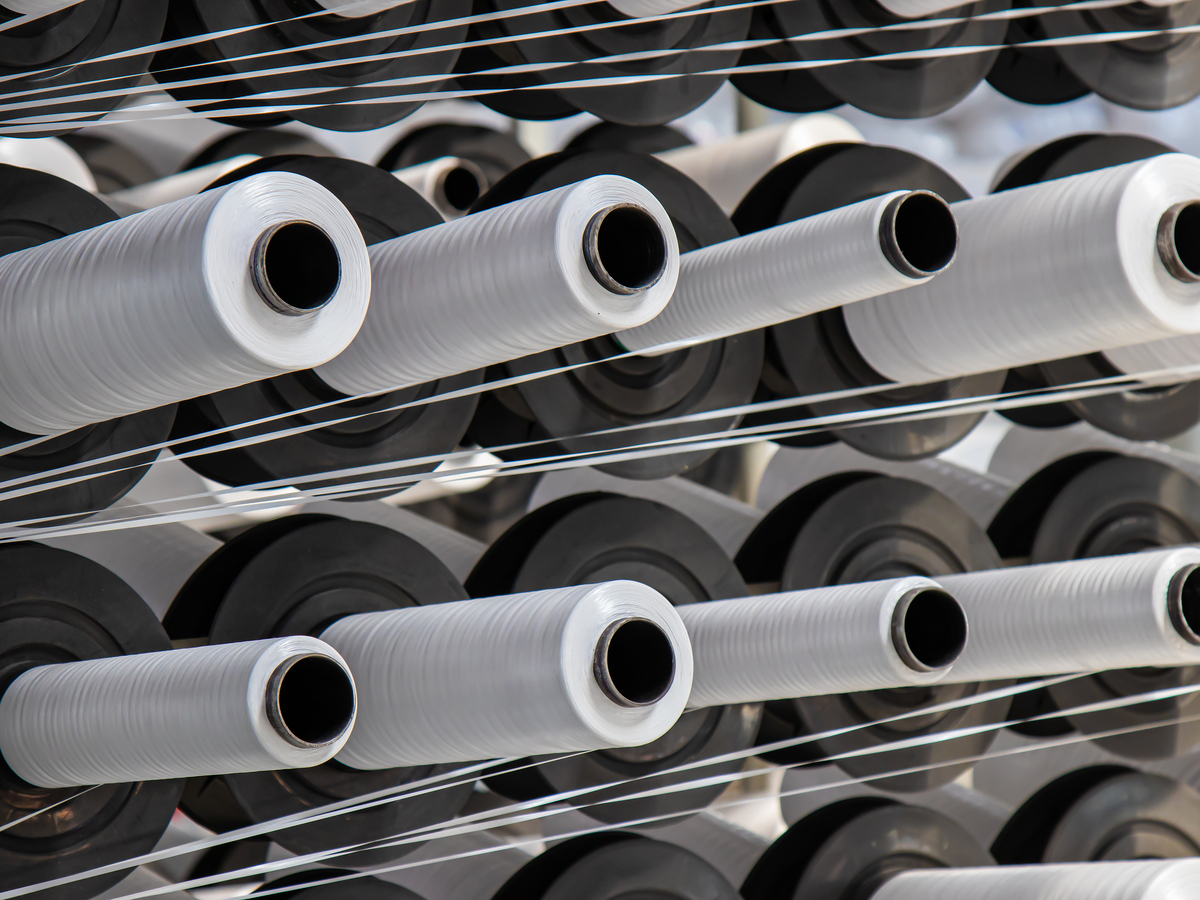

What we see

Spin beams used in the production of polyester, nylon, polypropylene, and other synthetic fibers can become clogged over time, leading to issues with polymer flow, temperature control, pressure regulation, and overall production efficiency. Traditional high-temperature burnouts often fail to completely remove stubborn polymer residues, resulting in reduced operational time between cleanings, costly quality issues, and downtime. If critical pathways are not fully cleared during each cleaning cycle, residues can solidify to the point where replacement becomes the only option.

What we do

At Carolina Process Equipment Cleaning (Carolina PEC), we employ a combination of safe, effective depolymerization chemistries and advanced high-temperature oxidation processes to thoroughly remove polymer buildup and residues that can constrict and block critical pathways in spin beams. Throughout the cleaning process, we perform comprehensive borescopic inspections to ensure all residual polymer and scale are eliminated, restoring your equipment to optimal operating condition.

By utilizing our specialized cleaning services, manufacturers can extend the operational lifespan of their spin beams, enhance production efficiency, and reduce the risk of costly downtime and quality issues.